We came a long Way

The beginnings of System Brunner

After his studies in chemistry at the University of Zurich, Felix Brunner immersed himself in the study of old printing techniques, resulting in the standard work “Handbook of Graphic Reproduction Processes” in the early 1960s. With this basis, he became production manager in a renowned international advertising agency in Zurich. In this position, he experienced the disappointment of clients on a daily basis when the print production did not achieve the color result of the proof print and had to constantly deal with customer complaints and the printers. At that time, printing was still a purely manual trade without any measuring technology.

The scientifically oriented basic attitude prompted Felix Brunner, from 1968 onwards, to conduct basic research into how these problems could be solved. In Corippo in the Verzasca valley in Ticino, he carried out studies and initial developments (print control strips) over a period of several years. By brokering reproduction orders between Italy and Switzerland, he earned his simple living and at the same time was able to test his developments in practice. During this time, the first measuring instruments (densitometers) for density control came into the market. After the colorimetric standardization of the CMYK scale colors to the “European scale”, the opinion prevailed under the leadership of the Fogra and UGRA research institutes that this solved the color problems between proof and print run in the offset printing process that was gaining acceptance.

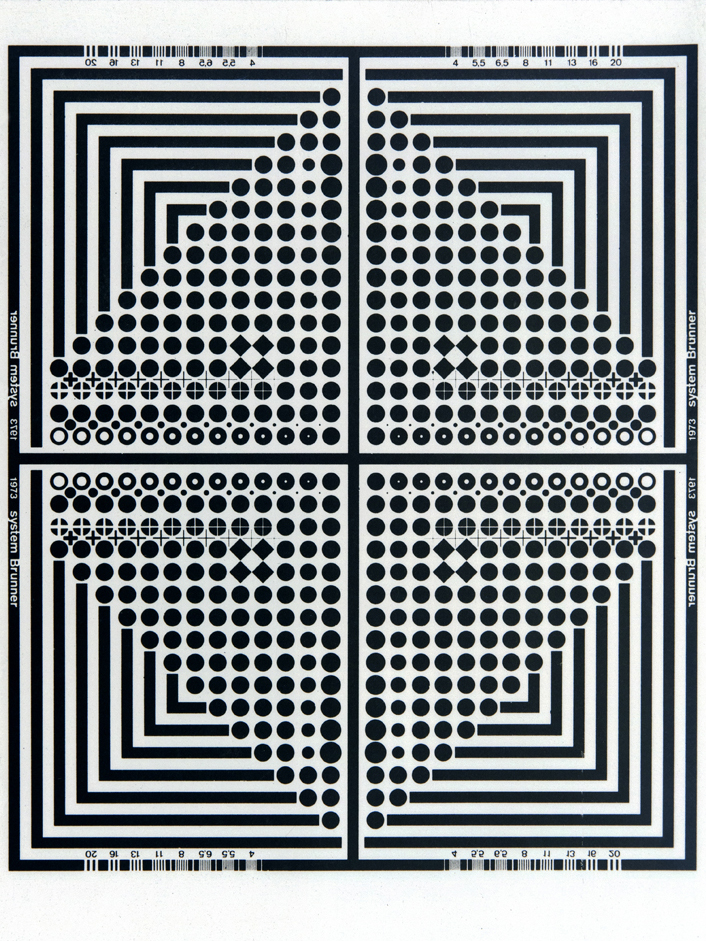

However, Brunner was the first to recognize that the differences in halftone dot gain resulted in much greater visual color differences than just controlling density in the solid. He developed the first methods for checking dot gain (coarse/fine screen method) and produced the first print control strips with which printers could measure and assess the print results themselves. This quickly led to better process reliability between the press proofs and the print run. He transferred his expertise in the legendary seminars in Corippo, which were attended by printers from all over Europe. Further measurement criteria were constantly being added. In addition to two-color trapping, the first control strips with three-color patches for visually checking the color balance followed as early as 1973.

The micro-measurement technique for printing plate control

Brunner observed large manufacturing differences in printing plate copy. As early as 1973, he developed a new method for precise plate control using micro-measurement technology and applied for an international patent for the technology. He had to defend the patent against the Swiss measuring device manufacturer Gretag (which belonged to the chemical multinational Ciba-Geigy, now Novartis) and initially the German Fogra Institute all the way to the German Federal Court in Karlsruhe, where a settlement favorable to Brunner was reached. Subsequently, System Brunner produced not only System Brunner’s high-precision print control strips and test forms but also those of Fogra, Heidelberg, Manroland, Komori, Dupont de Nemours and others with the integrated microline measuring technology under licensing agreements until the analog technology was replaced in the mid-1990s.

Eurostandard/Globalstandard® System Brunner

Because there were no “official” standards for standardization in the printing industry, System Brunner defined the first printing standards as early as the mid-1970s under the protected trademark “Eurostandard” and later “Globalstandard”. In addition to solid ink densities for coated and uncoated papers, tone value increases with characteristic printing curves, printing plate copy, 2-C trapping according to the Brunner formula and neutral CMY gray balance were defined. Colorimetric L*a*b* solid coloration was adopted from the Europe-Scale, but had minor importance. These standards were constantly expanded in the following years and adapted to technological improvements. The Brunner system spread throughout Europe. At Fogra’s request, System Brunner kept a low profile in the German market so that the institute would have an additional source of income from the control strips in addition to the state and industry association subsidies. UGRA also received a free license so that the Swiss institute could sell the UGRA printing plate wedge with microlines and thus secure an important source of income for years. In the 1990s, Fogra wanted to dissolve this “gentlemen’s agreement” and also become active outside Germany. In contrast to the institutes, System Brunner has always financed all its research and development activities itself. Felix Brunner was called the “father of printing standardization” in the printing industry.

Eurostandard Cromalin® with DuPont de Nemours

The cooperation with DuPont de Nemours began in 1978. System Brunner was able to show how the Cromalin® proofing method related to Eurostandard® Offset in terms of color during extensive developments and tests. The Eurostandard Cromalin® System Brunner was a unique success story for DuPont and System Brunner until the beginning of the 1990s. Certain differences from the standardized printing process remained, but proof production was much simpler and more stable in color than the usual machine proofs and also more cost-effective. As a result, this process became the market leader in Proofing throughout Europe. DuPont subsequently introduced the Eurostandard Cromalin® System Brunner in the USA and Japan from 1983 onwards, and made a major contribution to the international spread and acceptance of System Brunner.

Picture Contrast Theory (PCT)

In 1984 System Brunner published the Picture Contrast Theory (PCT) for the first time. Based on extensive basic research and tests, System Brunner was able to show that image contrasts have a very significant influence on the visual perception of color differences in image printing. The findings of the image analysis were later taken into account in the Instrument Flight® color control technology.

The influence of gray balance in the printing process

During the seminars and the practical application of the measuring technology and standards, it was often observed that the dot gain, solid ink densities and trapping between two prints were almost the same, but that clear color differences were still visible in the printed image. This led to further research at System Brunner and the realization that the three-color CMY overprinting behavior including 2-C trapping is another important influencing variable in the printing process, which must also be taken into account when controlling the printing process. This phenomenon was best captured using a three-color CMY gray field, which also reacts strongly visually to color drifts.

The measuring technology and inking unit control including gray balance

System Brunner subsequently developed a new measuring method for determining the gray balance on the basis of color and brightness deviations, independent of the individual dot gains, and as early as 1985 applied for a patent for a new method of inking unit control according to “selected relationships of the process colors”, which was then granted in Europe and the USA. The measurement technology was initially developed on the basis of multifilter densitometry, because spectral measurement equipment was not yet available to control the industrial printing process. Only later was the technology supplemented with spectral measurement data. Even today, System Brunner can therefore precisely perform gray balance-oriented color control with inline measuring systems without spectral measurement data.

This was the starting signal for the development of own software solutions for monitoring and controlling the printing process.

1986 Start of cooperation with MAN Roland Offenbach

1987 PRINT EXPERT® System Brunner: Software for metrological inspection of proof and print, which was distributed worldwide in cooperation with Du Pont.

1989 – 1991 Development of INSRUMENT FLIGHT® technology and software version 1.0 For the first time, color control of printing presses was based on more than 30 weighted parameters, especially gray balances, dot gain and solid ink densities.

Blind landing: at Sandy Alexander Inc. in Clifton USA and IRL, Lausanne, Switzerland, the first fully automatic color matching with total visual match between proof print and print run result took place.

5-star quality evaluation of print results based on >30 weighted metrological parameters allows a quick assessment of how well the print matches the specified print standard.

However, the market was not yet ready for this groundbreaking technology at the beginning of the 1990s. For this reason, System Brunner only licensed these new products to selected consulting customers in the following years, who successfully implemented the technology in the long term to increase productivity and quality, while at the same time reducing costs.

The INSTRUMENT FLIGHT® software was continuously further developed and enhanced.

1993 System Brunner Quality Categories™: System Brunner for the first time publicly presents the market-related quality requirements for print products in 5 different categories, with an intended reference to the well-known hotel categories.

From analog to digital process control

1990 Development of the first digital print control strips and test forms for the emerging transformation from analog to digital imaging technology.

1994 – 1998 Development of methods and solutions for quality assurance in the digital workflow: EUROSTANDARD CHECKER Proof / CtF / CtP /Print.

Inline color management INSTRUMENT FLIGHT® on heatset web presses

1999 – Present: Cooperation with QUAD TECH Inc. for inline inking unit control INSTRUMENT FLIGHT on Heatset presses. After the takeover by Baldwin, the cooperation is continued.

The American technology company became aware of System Brunner INSTRUMENT FLIGHT because the existing inline ink control based on solid ink density did not achieve the desired color reliability in web offset printing.

System Brunner adapted the Instrument Flight technology for web offset printing. In the following years, together with QUAD TECH, more than 600 web presses worldwide were successfully introduced into production with the inline measuring system CCS and Instrument Flight, making Quad TECH the market leader in this sector.

From 2008, the complete re-design of INSTRUMENT FLIGHT and the processing of spectral measurement data with SpectralCam took place.

2004 okBalance® for manroland sheetfed presses: The special implementation is based on INSTRUMENT FLIGHT® technology and controls the print production after the definition of the color OK sheet with priority on gray balance.

In 2015, okBalance®2.0 is extended with the G7® evaluation for the American and partly Asian market.

To date, okBalance® has been licensed with hundreds of manroland presses.

Inline color management INSTRUMENT FLIGHT® with Koenig & Bauer sheetfed presses

2010 – Present: Cooperation with Koenig & Bauer sheetfed and implementation of INSTRUMENTFLIGHT® technology in the QualiTronic/ErgoTronic inline color control systems.

2012 INSTRUMENT FLIGHT® 3.0 with further functions and the new Color Balance Control Priorities™.

System Brunner performs training and process integration at customer sites for all Instrument Flight projects with Quad Tech and Koenig & Bauer.

2016 INSTRUMENT FLIGHT® becomes the world’s first color management solution for production printing to be certified by the IDEAlliance (USA).

2021 Development of Hypersphere® technology for inline color control with RGB measuring sensors

2022 Launch of System Brunner EQUALIZER™ software for easy process calibration, especially on non-ISO standard-compliant materials in packaging printing. Uses an adapted gray balance algorithm from the Instrument Flight technology with conversion of the profiles into area coverage values for RIP calibration.

Impressions